The stages of microbial fermentation at the molecular level

Microbial fermentation is based on a fundamental biochemical principle: the conversion of a substrate by microorganisms into one or more molecules of interest.

The substrate is the raw material, meaning the source of carbon and energy. The most commonly used is glucose. Other sugars derived from biomass can also be used depending on production goals.

Microorganisms are the key players in the process. Each species has a specific metabolism and enzymatic pathways that determine the final products. Different microorganisms—yeasts, bacteria, or fungi—are selected depending on the desired outcome.

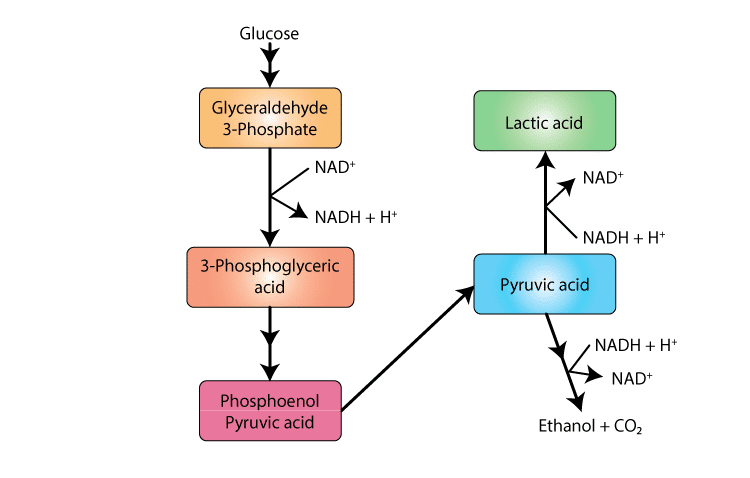

To better understand fermentation at the molecular level, let us take glycolysis as an example:

It is a metabolic pathway for glucose assimilation and energy production, forming the basis of fermentation.

It occurs in the cell cytoplasm and consists of a series of enzymatic reactions that break down glucose into pyruvate.

From pyruvate, several fermentation pathways are possible depending on the type of microorganism, the medium composition, and environmental conditions such as pH, temperature, oxygenation, and nutrient availability.

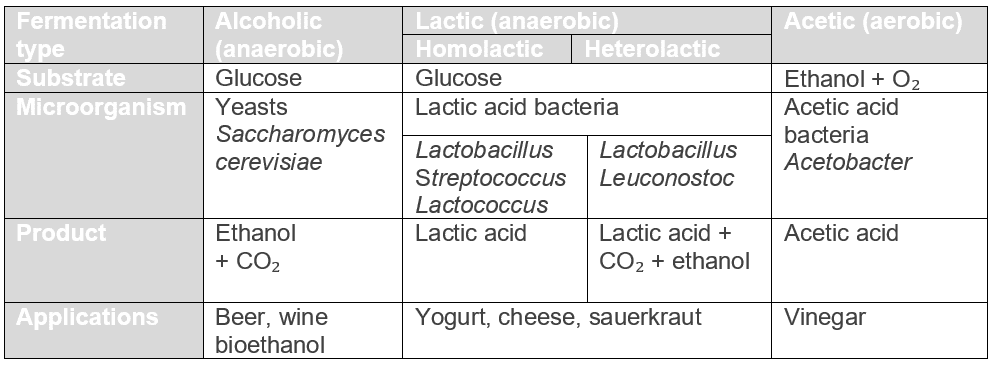

The different types of microbial fermentation

Each microorganism, depending on its metabolism, enables the production of specific molecules of interest according to the final objective. There are three common types of microbial fermentation:

Other types of microbial fermentation include:

Butyric: glucose or lactate → butyric acid

Propionic: lactic acid or glucose → propionic acid + acetic acid + CO₂ + H₂

Malolactic: malic acid → lactic acid + CO₂

Acetone-butanol-ethanol (ABE): glucose → butanol + acetone + ethanol

This metabolic diversity highlights the industrial potential of living organisms: the same substrate can yield a wide variety of valuable molecules depending on the strain and process used.

Microbial fermentation at the industrial level: The bioreactor

Thanks to its expertise, Ennolys has industrialized this artisanal and natural process to develop natural ingredients through microbiological pathways. Fermentation is carried out in bioreactors, large-scale fermenters, in which every parameter is precisely controlled: temperature, pH, agitation, pressure, oxygenation, and nutrient supply.

Microbial growth occurs in three phases:

Lag phase, during which the strain adapts to its environment;

Exponential phase, characterized by rapid cell multiplication and high production of primary metabolites;

Stationary phase, during which cell growth slows. Depending on the microorganism and product, primary metabolite production may continue or stop, while secondary metabolite synthesis may begin.

The resulting fermentation products include:

Primary metabolites (formed during growth): organic acids, alcohols, gases;

Secondary metabolites (formed after growth): pigments, antibiotics, natural flavors;

Biomolecules: enzymes, peptides, probiotics.

To ensure purity and quality, the obtained products are isolated and purified through downstream processing (DSP) steps: centrifugation, filtration, distillation, extraction, chromatography, etc. At Ennolys, our Quality & Compliance Control department oversees these operations to deliver high-quality products that meet our customers’ requirements. Our site is certified FSSC 22000, ISO 9001, FAMI-QS, as well as Halal and Kosher, ensuring reliability, traceability, and compliance.

Microbial fermentation: which industrial applications?

Whatever the need, Ennolys applies its microbial fermentation expertise across multiple sectors.

Nutraceuticals: production of bioactive compounds such as vitamins, probiotics, and natural flavors.

Cosmetics: production of ingredients such as hyaluronic acid, bioactive peptides, and enzymes integrated into a wide range of products.

Food industry: the foundation of many foods (yogurt, cheese, bread, wine, sauerkraut) and production of food additives such as organic acids, natural flavors, and colorants.

Beyond these sectors, microbial fermentation also offers opportunities in:

Biotechnology and green chemistry: production of molecules such as acetone, butanol, and biopolymers;

Textile and paper industries: production of industrial enzymes;

Energy: production of bioethanol and biogas for energy and biofuels;

Environmental protection and waste treatment: waste valorization and biological treatment.

Optimizing fermentation yields: 5 mistakes to avoid

Fermentation is a biochemical process involving numerous parameters, all of which directly impact yield.

Poor strain selection

The microbial strain determines productivity and process stability. Its industrial-scale performance must be validated.

Non-optimized substrate

An unsuitable substrate can limit growth or generate undesirable by-products. Selecting the optimal substrate from the outset improves performance and controls costs.

Poorly controlled oxygenation

Oxygen strongly influences metabolic pathways—even in anaerobic fermentations. Too little or too much oxygen can reduce productivity or create unwanted metabolites.

Undersized DSP

Downstream processing is as critical as fermentation itself. Poor recovery or purification planning can result in yield losses, higher costs, or insufficient product quality.

Underestimating scale-up

Laboratory conditions cannot be directly transposed to pilot or industrial scale. Neglecting scale-up effects can lead to productivity gaps and delays.

Microbial fermentation is a cornerstone of biotechnological innovation and an indispensable solution for numerous—if not all—industries: food, nutraceuticals, chemistry, and beyond. By harnessing the processes of living organisms and the essential role of microorganisms, fermentation enables the sustainable production of valuable molecules, paving the way for greener, more circular chemistry.

At Ennolys, a subsidiary of Lesaffre, a global leader in fermentation for over 170 years, we put our expertise at the service of industry to design and produce high value-added molecules and natural flavor solutions, driven by innovation and sustainability.

Through its Ennatech offering, Ennolys also provides fermentation, purification (DSP), and drying services, supporting projects from laboratory scale to full industrial production.